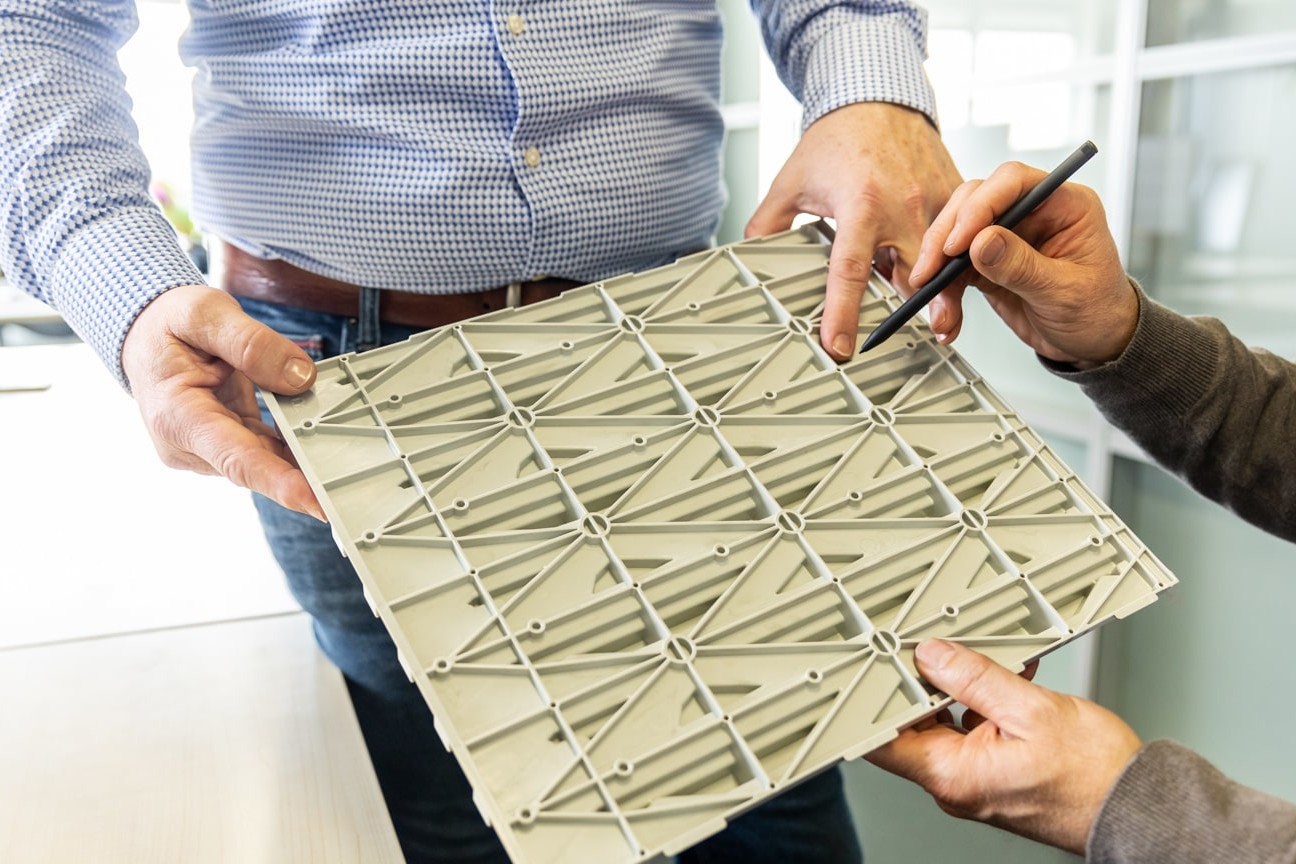

Your idea, our precision

Do you need a product or component fully tailored to your application?

Custom moulding is the opportunity to make a difference: a solution tailored to your sector, your volumes, and your ambitions.

At Didak Injection, we work with you from the start—from design to mould, from choosing the material, to production.

The earlier you involve us, the smarter we can build.

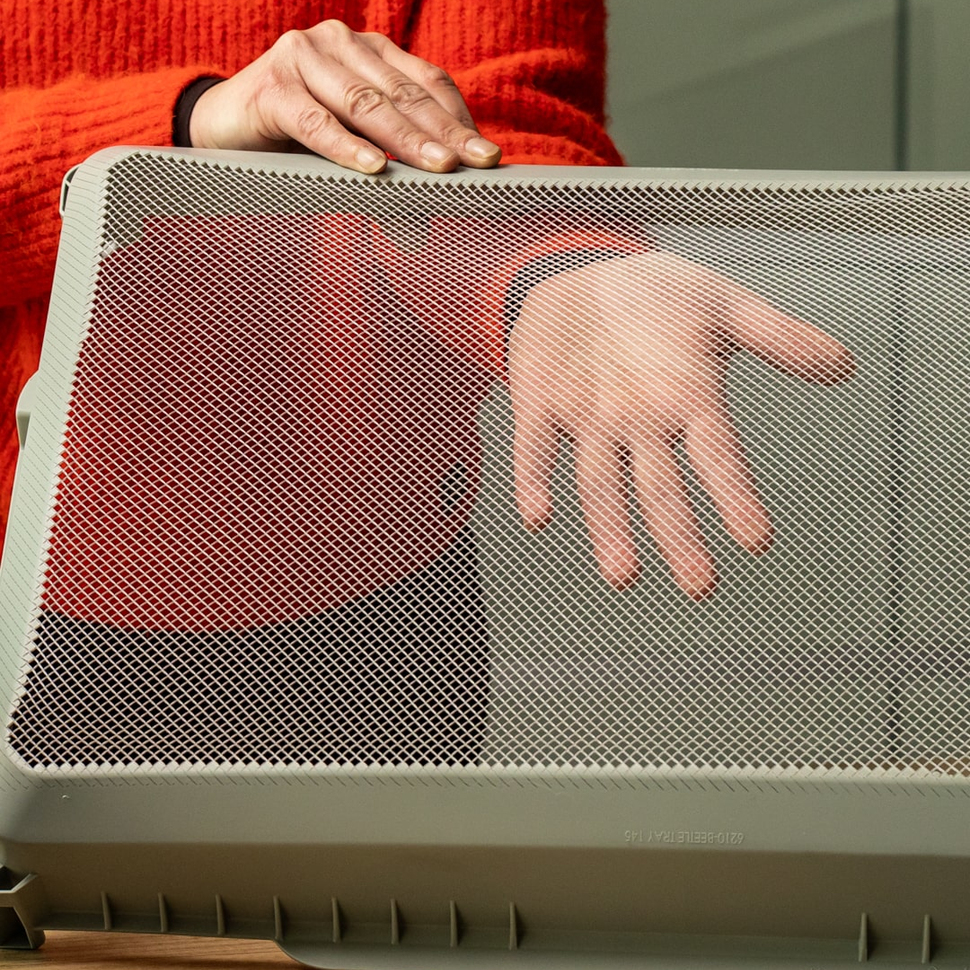

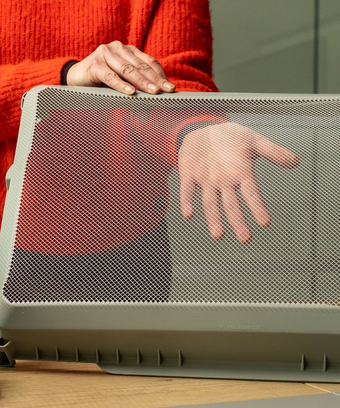

From concept to final product – together, and tailored

Whether it’s about shape, size, or function: we develop injection moulding solutions that fully meet your technical requirements.

We take into account:

- reusability

- production flows

- choice of material

- volume requirements

We produce moulds to measure, in collaboration with our trusted partners.

This guarantees quality, speed, and full control.