Research & Development

From first concept to production-ready design

Have an idea or concept? We shape it with you.

From the first sketch to a production-ready design, we guide you in optimising functionality, durability, and production technique. All while maintaining a fair price-to-quality ratio. This includes the manufacturing of prototypes and the actual moulds for plastic injection moulding.

Even if you already have a technical design, we advise on improvements and material choices—always with an eye on reusability and recycling.

We process a wide range of materials, from bulk resins (PE, PP) to engineering plastics (ABS, PP, POM). Our engineers work with you to choose the material with the best properties for maximum reusability and strongly focus on recycling.

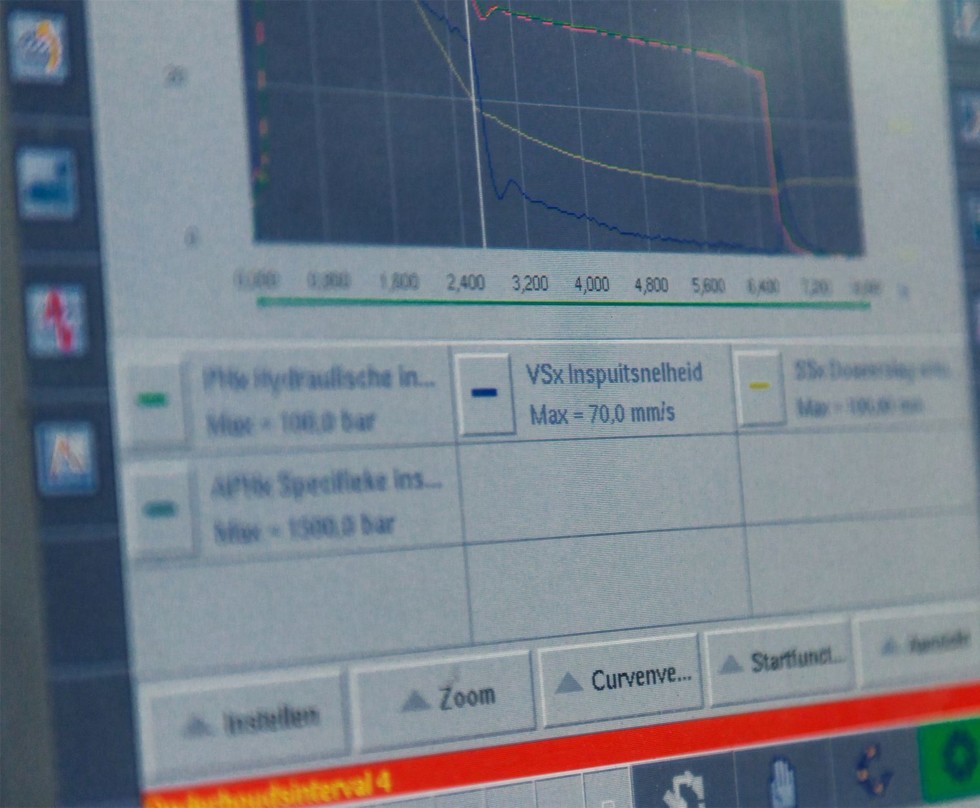

Tech Lab

Smart technology, smart applications

Innovation doesn’t stop at materials.

In our Tech Lab, we combine IoT, RFID, Google, and other technologies to make your product smarter and more functional.

From multi-component injection and insert moulding to in-mould labelling and dual techniques—we build reusable plastic solutions that do more than just package… they improve your logistics flow, visibility, and brand experience.

Multi-component injection

This technique allows Didak Injection to process multiple materials with different properties, colours, or hardness levels into one end product in the same mould.

Gas injection

With gas injection, we produce hollow plastic products. After partially or fully filling the mould with liquid plastic, an inert gas is injected under constant pressure. This creates a hollow wall. The technique offers extra design freedom. Material savings and added strength are additional benefits.

Insert moulding

A technique in which a non-plastic component is overmoulded with plastic—for example, when placing an insert or reinforcing a plastic product.

In-mould labelling

Printed plastic film is placed in the mould and is embedded in the product after injection moulding.

Dual techniques

Our many years of expertise allow us to integrate various dual techniques. Whether it’s about combining different materials within a single design or using various color combinations, our machinery enables us to meet even the most specific requirements your product needs to fulfill.

A major advantage of dual techniques is that they enable the creation of complex products with different properties in one piece. Because this is integrated into the injection process, no post-assembly is required. This allows us to create unique products using hard and soft materials or various colour combinations.

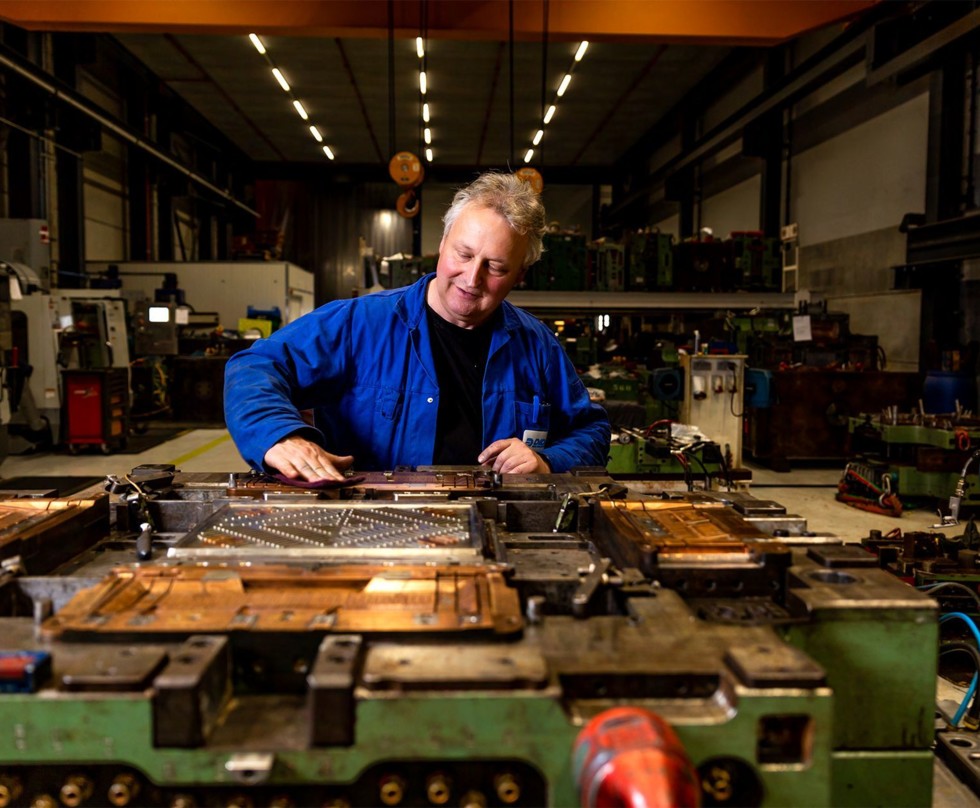

Mould service

Automatic packaging line

Efficient to the very end

We don’t just think about the product—we also think about the packaging.

Our fully automated packaging line ensures:

- Efficient loading & wrapping

- Recyclable packaging material

- Error-free deliveries thanks to 2- or 4-sided labelling

- Less waste, more sustainability

In short: your product, perfectly packed and ready for delivery.

Whatever your project needs—we think along.

Let us know what you need, we’re happy to help.