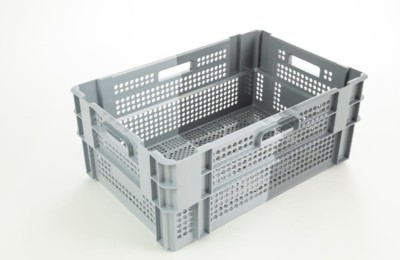

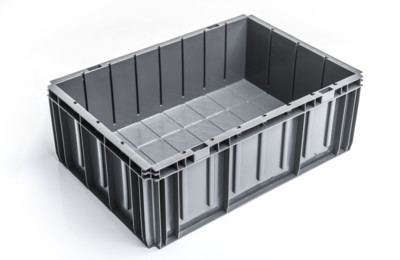

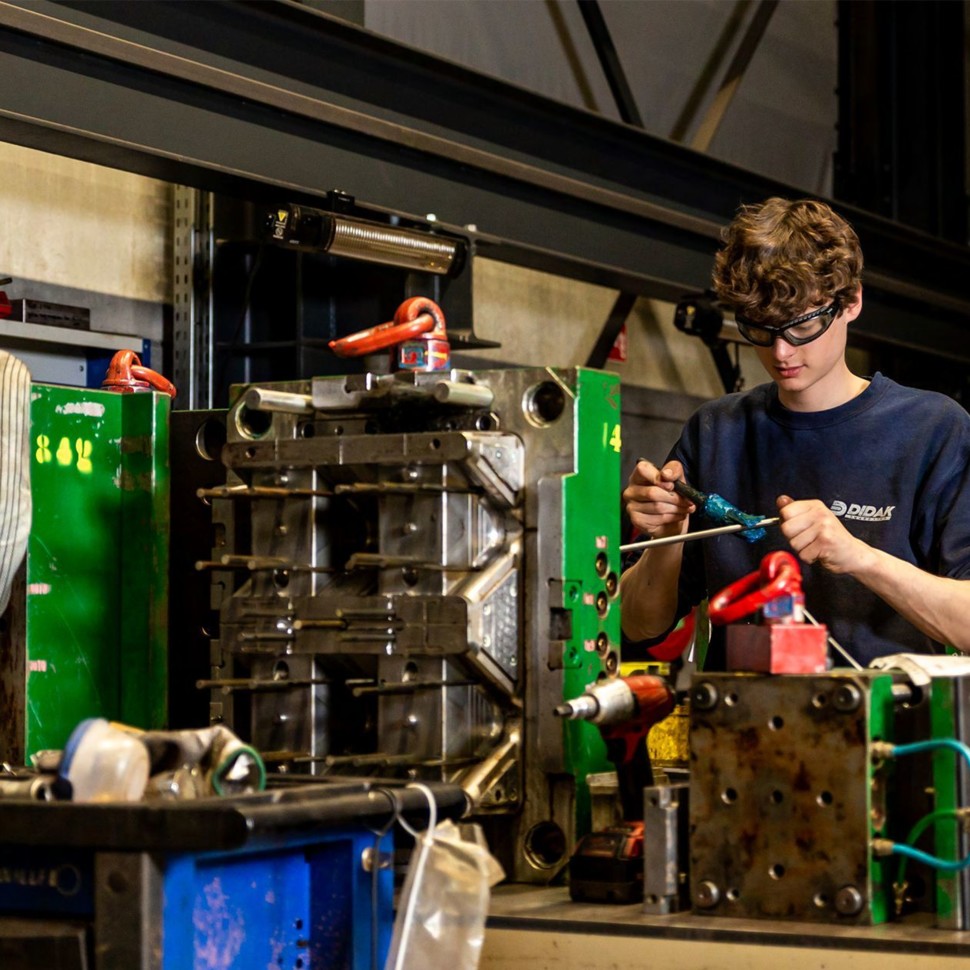

At Didak Injection, we develop plastic solutions that go beyond the standard. From design to mould, from prototype to series production: we think with you every step of the way. With over 50 years of experience, we deliver stacking crates, tailor-made solutions, and high-quality custom moulding.

Fast, efficient, and reliable.

We gladly work with you to find the best solution.