Custom moulding does not start at the mould design stage.

It starts with a question.

What does this component need to do? In what conditions will it be used? What forces must it withstand? And just as importantly: how does it fit into the overall product, the process, and the customer’s application? That way of thinking is deeply rooted in our approach. Because only when you truly understand the use and context can you develop a plastic solution that is not only technically feasible, but also reliable, repeatable and sustainable in the long term.

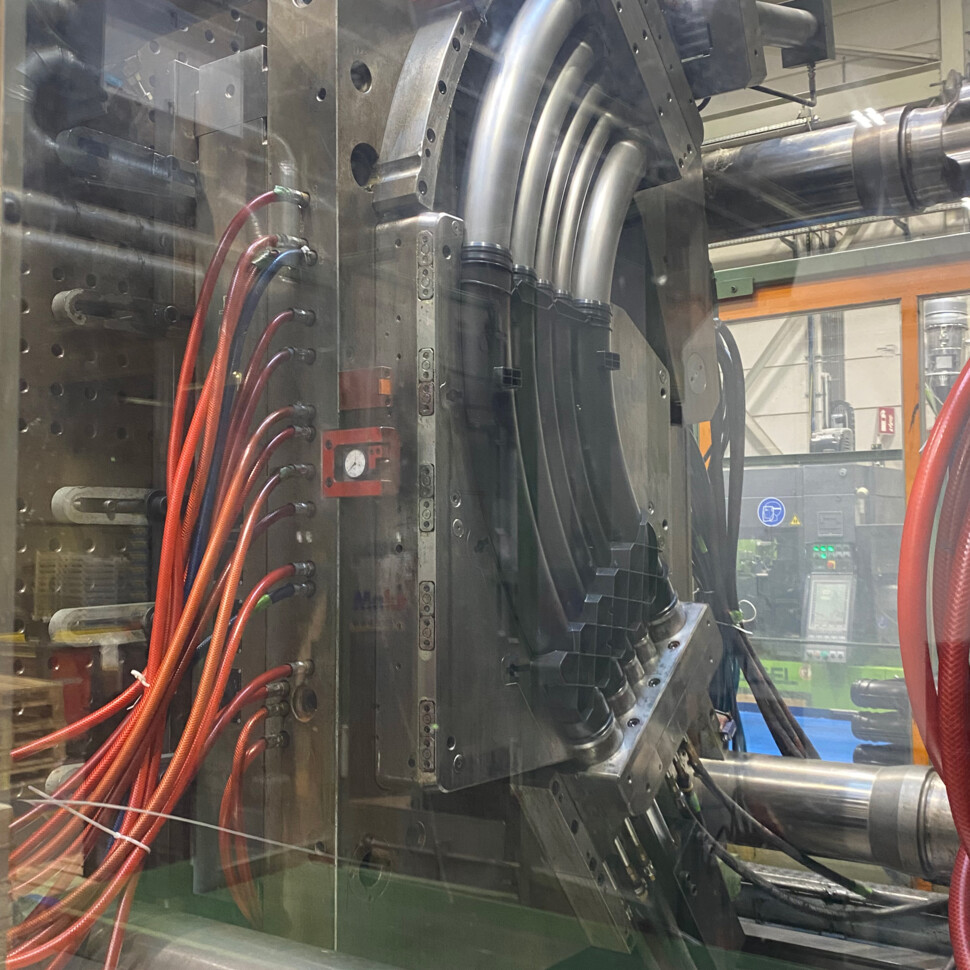

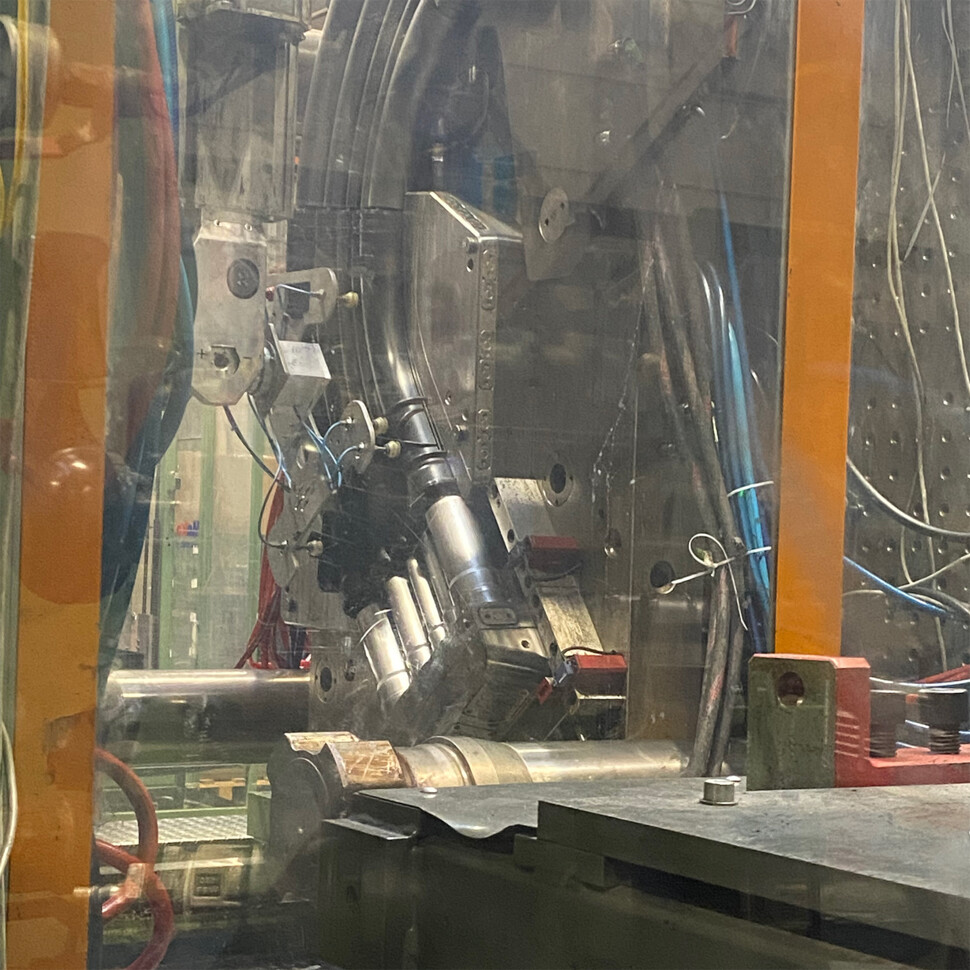

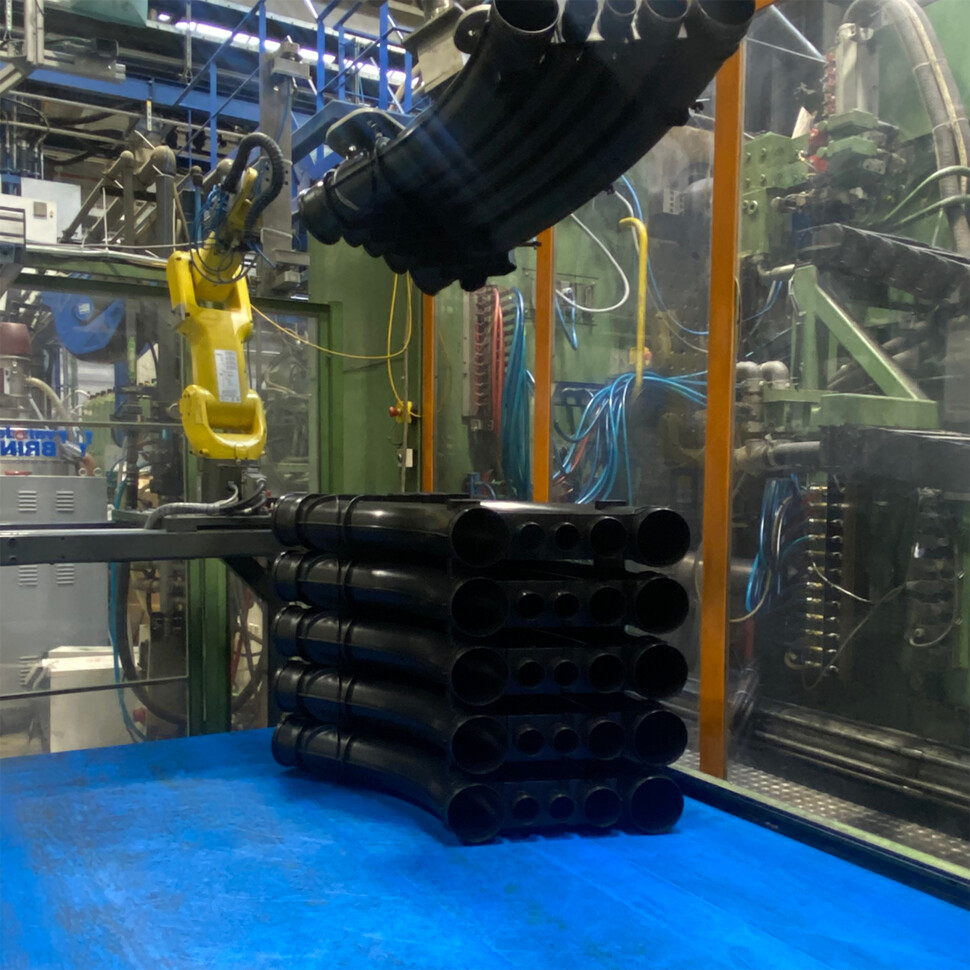

A recent project—a complex hollow bend—is a perfect illustration of this.